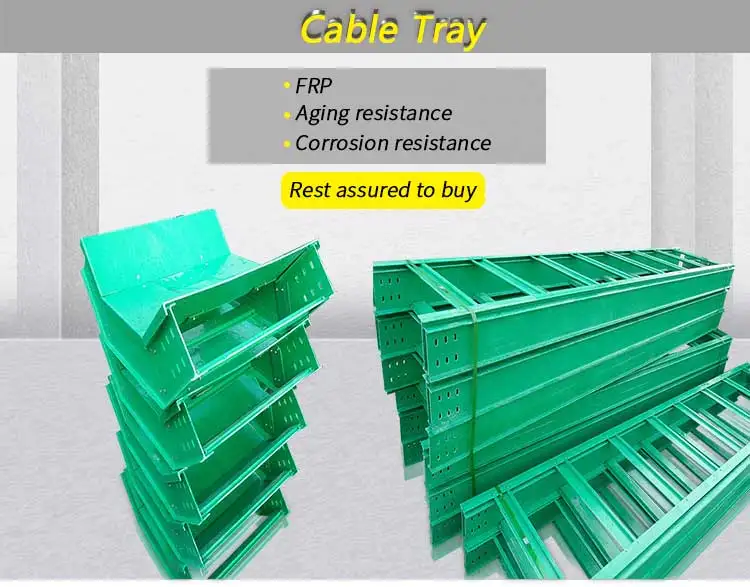

Fiberglass Reinforced Plastic FRP Cable Tray

Cable Tray Features:

1. Low cost, significant cost savings compared to standard traditional tray products.

2. Light in weight, wide range of sizes.

3. Fast heat dispersion.

4. Strong enough to withstand short circuits. Provides strength, rigidity without additional hardware.

5. Adapts to difficult architectural designs to accommodate changes in direction and elevation of cable runs.

6.Flexible, easy and fast installation. Design allows cable exit or entry at any point.

7. Cables can be secured to clamps or ties.

8.Various hardware accessories available to fix, support and install.

9. Safe smooth edge design to protect cable.

10.Easy for line check and cleaning , easy maintained.

Cable Tray Structure Types:

1. Groove series.

2. Stepped series.

3. Tray series.

FRP Cable Tray Specifications:

1. Width:100mm,150mm,200mm,300mm,400mm,500mm,600mm,800mm,etc.

2. Height: 50mm,100mm,150mm,200mm,etc.

3. Length: 1000mm,1500mm,2000mm,2500mm,3000mm,etc.

4. Material: FRP, SS304, Hot dipped galvanized steel,etc.

FRP Cable Tray Applications:

DHQ series of FRP bridge used in voltage under 10 kv power cable, as well as the control cable, lighting, pneumatic,

hydraulic pipe line and other indoor and outdoor overhead in cable trench, the laying of the tunnel.

Fiberglass Cable Tray Structure Characteristics DHQ series of FRP bridge has a wide application, high strength,

light weight, reasonable structure, low cost, long service life, strong corrosion, simple construction, flexible wiring,

installation standards, the characteristics of beautiful appearance.

Fiberglass Cable Tray Fiberglass Cable Tray,Cable Tray,Light Duty Cable Tray,Ladder Cable Tray Hebei Long Zhuo Trade Co., Ltd. , https://www.hblongzhuo.com

Introduction of a new type of intelligent valve control module

DSM modular intelligent electric valve controller, the use of advanced micro-processing technology, high integration of IC chips and long-life power output devices, to accept from the host instrument DC4 ~ 20mA adjustment signal and the lower electric actuator DC4 ~ 20mA valve position feedback Signal (or potentiometer "three-wire" signal), the output "on" and "off" signal to achieve the valve opening control and regulation. DSM modular intelligent electric valve controller, with digital setting, display, limit, motor stall protection, break alarm and valve self-calibration and other advanced features. Reliable, stable and precise control of the valve, damper and baffle adjustment structure. Can be widely used in power generation, metallurgy, petroleum, chemical and other fields. The DSM Modular Smart Electric Valve Controller can be used with single-phase AC motor actuators such as the DKJ and DKZ actuators, but also with actuators and actuators for three-phase AC motors. DSM modular electric valve controller with the use of the traditional electric valve, the reliability, stability, accuracy, etc. can be increased more than several times, for the transformation and upgrading of the old electric actuator has brought a new life. Main features: ◠Intelligent calibration: No need to adjust the potentiometer for "zeroing" and "full" calibration of the valve position opening and valve position output current, without complicated debugging with the reference measuring instrument, as long as the actual valve The "all off" and "fully open" position by pressing the button, it automatically correct the newly set range of 0-100% and DC4-20mA. ◠Digital setting of electric zone parameters, minimal overshoot, good stability, high control accuracy. ◠open to freedom: to change the valve opening and valve mode, no need to change any wiring, set by the button to complete. ◠intelligent step: to avoid oscillation or "Chong" phenomenon, improve control accuracy. ◠Super error detection and alarm function: In the event of actuator failure, intelligent error detection and alarm function can automatically detect and alarm, display the cause of the actuator failure, accurately indicate the operating status of the actuator. Depending on the cause of the fault, the display of different alarm signals will greatly shorten the time required for the user to eliminate the fault and return the actuator to its normal working condition as soon as possible. ◠Automatic phase protection: In the past, when wiring in the field, the phase sequence of the three-phase AC power supplied to the actuator must be guaranteed to be correct because once the phase sequence is wrong, the motor will be rotated incorrectly and the valves and actuators will be damaged. Users can now save this trouble, no longer need to consider the phase sequence wiring problems. When the phase of the field wiring is reversed, the phase synchronizer will automatically correct the phase to ensure that the valve is executed in the direction of the command. That is to say, the actuator always rotates in the pre-set opening direction when it receives the opening command, and will not run in the opposite direction due to the phase sequence exchange. ◠Abnormal protection: Motor overcurrent protection: When the actuator motor is running, the motor overcurrent due to various reasons, DSZH220 will automatically stop the motor. Instantaneous reverse protection: When the actuator is turning in one direction, for example, the valve opening operation is being executed. If the valve closing command is received, the control logic inside the actuator will be delayed for a preset period of time before the valve closing command is executed . This technology will reduce the impact of motor current, extend the life of power components, while preventing the impact load on stem, gear box and other mechanical transmission may cause damage, and thus effectively protect the motor. Valve Jam Protection: If the actuator does not overcome the torque required to start the valve, the valve jamming condition already exists. When the actuator receives the start signal of on or off, if the valve is stuck and does not operate for a preset period of time, the internal circuit will open the corresponding contact and forcibly suspend the operation of the actuator. At the same time, the corresponding Alarm signal, in addition the signal can also be output through RS485. ◠Digitally set the alarm and protection mode when the input signal is disconnected. ◠Adopt non-loss readable and writable storage device, easy to change parameters, permanently save power. ◠Automatic / manual switch without disturbance, good anti-interference. (The motor is directly controlled by the actuator of AC220V, and the actuator of AC380V is AC380V power actuator.) Technical Data 1. The scope of application · Applicable Actuator: Supply voltage 220V ± 15% (AC), power less than 150W, common end, open, closed three-wire control on, off, stop the motor. · Working environment: Ambient temperature: -20 ℃ ~ 55 ℃. Relative humidity: less than 90%. 2. Input signal · Adjust the input signal: 4 ~ 20mA (DC), the input load impedance is less than 150Ω. · Opening input signal: Potentiometer signal, 500Ω ~ 5KΩ. 3. Output signal · Valve position feedback output signal: 4 ~ 20mA (DC, isolated), output with load capacity less than 450Ω. Switch control signal: relay output. Contact capacity: 5A, 250V (AC). 4. Control accuracy · Sensitivity: 0.2% ~ 3.0%. 5. Description of operation · Function selection: press the "Function" key, the function will be transferred from the current function to the next function in 2 seconds. The direction of the cycle is: Auto (Function indicator lights up) -> Manual (Function indicator goes out ) -> Parameter setting 1 (Function indicator flashes rapidly) -> Parameter setting 2 (Function indicator flashes slowly) -> Automatic (Function indicator lights up). · Calibration: Press and hold the "Adjust" button when the non-setting mode is in place, and confirm the position is the fully open position after 2 seconds, the valve full-on indicator blinks for 2 seconds to confirm; · Setting: Press and hold the " "Key is not released, 2 seconds after the current function into the next function. Repeat the above operation until parameter setting 1 is entered (the function indicator blinks at this moment). Through the "adjust" button to set the sensitivity mode, open, enter the break mode. The three parameters are expressed in 4-bit binary. The "Adjust" key causes the value to decrease cyclically (1111 -> 1110 -> 1101 -> ... -> 0000 -> 1111). Press the "Function" key to exit the parameter 1 setting, the above parameters are automatically saved. Press and hold the "function" button is not released, 2 seconds after the current function into the next function. Repeat the above operation until parameter setting 2 is entered (the function indicator will flash slowly). Set the sensitivity value by "Adjust" button. This sensitivity value is expressed in 4-bit binary and the "adjust" key decreases the value cycle (1111-> 1110-> 1101-> ...-> 0000-> 1111), which means setting the sensitivity mode in parameter setting 1 Sensitivity value for fixed mode. Press "Function" again to exit Parameter 2 setting, the above parameters will be automatically saved. (After setting the sensitivity to auto-tuning mode in parameter setting 1, parameter setting 2 will not appear in the function selection cycle. The sensitivity value will be automatically calculated by the module and adjusted in time.) · Manner of operation: Press and hold "Function" Key is not released, 2 seconds after the current function into the next function. Repeat the above operation until it is in manual mode (the function indicator is off). Shut down through the "function" button (press the time to keep less than 2 seconds, otherwise that is the function of choice), "adjust" button to open the valve, valve operation. During the opening process, the valve is turned on (ie, a digit of a lamp) flashes to the fully open position, and the valve is turned off (ie, the digit 0) to be switched off. The valve can be stopped by pressing the "Adjust" key while the valve is open or by pressing the "Function" key when the valve is closed (for less than 2 seconds). Automatic: Press and hold the "Function" button does not release, after 2 seconds from the current function to the next function. Repeat the above operation, until enter the automatic state (function indicator light), automatically control the valve open, close, stop, so that the valve opening and adjust the input line. 6. Software Features · Commutation delay protection. · Automatic Kam. * Automatic adjustment of jogging range, step. Hand or self-adjusting sensitivity (dead zone). Open to the freedom of setting. · Input disconnection mode selection (on, off, centering, stop). 7. Settable Control Parameters • The setup parameters are completed with the "Function" key and the "Adjustment" key. The set parameters are also displayed by one function indicator (green) and 4 digit indicators (red). • During parameter setting, the "Function" key is used to select and save the parameter settings. The "Adjustment" key is used to adjust the parameter values. Refer to the function selection and setting terms in the above operating instructions. · During the parameter setting, indicator LED1 displays bit 0 (BIT0) of the setting parameter. On indicates that the bit is 1. Off indicates that the bit is 0. LED2 displays the first digit of the setting parameter (BIT1 ), Light on behalf of the bit is a light off behalf of the bit is 0; indicator LED3 display set parameter bit 2 (BIT2), light on behalf of the bit is 1 light off behalf of the bit is 0; LED4 Bit 3 (BIT3) of the setting parameter is displayed. On indicates that the bit is 1 Off. • Sensitivity mode is indicated by LED4 (BIT3) when the parameter setting 1 is set (Function Indicator Blinks Fast) (BIT3 is 0: Hand Tune, Sensitivity Value is set in Setting Mode 2; BIT3 is 1: (BIT2 is 0: forward direction; BIT2 is 1: reverse direction) is indicated by LED3 (BIT2), input break mode is indicated by LED2 and LED1 (BIT1BIT0) Set; BIT1 BIT0 is 10: closed valve; BIT1 BIT0 is 11: open valve). • Sensitivity value is indicated by LED4 ~ LED1 (BIT4 ~ BIT0) when setting state 2 (function indicator is flashing slowly) (BIT3BIT2BIT1BIT0 is 0001: Sensitivity is 0.2%; BIT3BIT2BIT1BIT0 is 0010: Sensitivity is 0.4%; BIT3BIT2BIT1BIT0 is 0011 : Sensitivity 0.6%; ...; BIT3BIT2BIT1BIT0 1111: Sensitivity 3.0%). • For example, when parameter 1 is set (function indicator blinks), if LED4 is off and LED3, LED2, and LED1 are on, parameter 1 is 0111 in 4-bit binary. Its LED4 light off (BIT3 = 0) indicates that the sensitivity is the parameter value setting in parameter setting 2, its LED3 is on (BIT2 = 1) indicates the reverse control (4mA full 20mA off), and its LED2, When LED1 is lit (BIT1 BIT0 = 11), it indicates that the valve is fully open when the input is disconnected. When set state 2 (function indicator flashes slowly), if LED4 is lit and LED3, LED2 and LED1 are off, then parameter 2 is represented by 4 binary values ​​of 1000, which means that the sensitivity value is set to 1.6% . 8. Interface RS232 RS485