Christmas Eve Box,Christmas Eve Chocolat Cookie Box,Christmas Eve Packaging Gift Box,Christmas Apple Packaging Cans Dongguan Tielangtou Hardware Products Co., Ltd , https://www.tinboxtlt.com

Major Pharmaceutical Company Saves Using the Elios 2 for Tank Inspections

# Major Pharmaceutical Company Achieves Significant Savings with Elios 2 for Tank Inspections

A prominent pharmaceutical company recently utilized the Elios 2 drone for conducting critical tank inspections during Riboflavin testing. This innovation brought about impressive results, streamlining operations and enhancing safety.

## Key Benefits at a Glance

| **Benefit** | **Details** |

|-------------------|-----------------------------------------------------------------------------------------------|

| **Cost Savings** | Reduced downtime by 60,000 Euros in a single inspection round covering five tanks. |

| **Personnel Reduction** | Decreased the number of inspectors from five to three, making the process more efficient. |

| **Enhanced Safety** | Eliminated the need for inspectors to physically enter tanks, improving overall safety. |

---

## Introduction

Large-scale tanks play a crucial role in pharmaceutical manufacturing, often constructed from stainless steel due to its superior cleaning properties. Maintaining cleanliness is essential throughout the manufacturing process, especially after each production cycle.

Acid and lye are typically used to clean these tanks. However, when introducing a new tank or implementing a novel cleaning procedure, health and safety teams must rigorously confirm that all contaminants have been eliminated. This involves spraying a fluorescent substance known as Riboflavin onto the tank's interior using a long rod to ensure thorough coverage. After application, the Riboflavin is cleaned off to assess the effectiveness of the cleaning protocols.

This protocol, referred to as a "Spray Shadow Test" or "Riboflavin Test," ensures that cleaning procedures meet stringent standards, acting as a surrogate for potential contaminants. If residual Riboflavin persists after initial cleaning, adjustments must be made until the cleaning process proves effective.

Traditionally, this process requires personnel to physically enter the tank twice: once to confirm full coverage and again after cleaning to ensure no Riboflavin remains.

---

## Customer Requirements

Based in Austria, this pharmaceutical giant operates several sizable tanks at their production facility. They sought innovative solutions to expedite the Riboflavin testing process, aiming to minimize downtime and cut costs while exploring the feasibility of remote inspections. Their goal was to eliminate the need for staff to physically enter the tanks, thereby improving operational efficiency and safety.

---

## AEROVISION Drone Support GmbH Delivers Cutting-Edge Solution

Markus Rockenschaub of AEROVISION Drone Support GmbH, an Austrian-based drone inspection service provider, proposed leveraging Flyability’s Elios 2 for the upcoming Riboflavin testing round. Designed specifically for confined-space inspections, the Elios 2 proved ideal for navigating the tanks safely and efficiently.

---

## Results

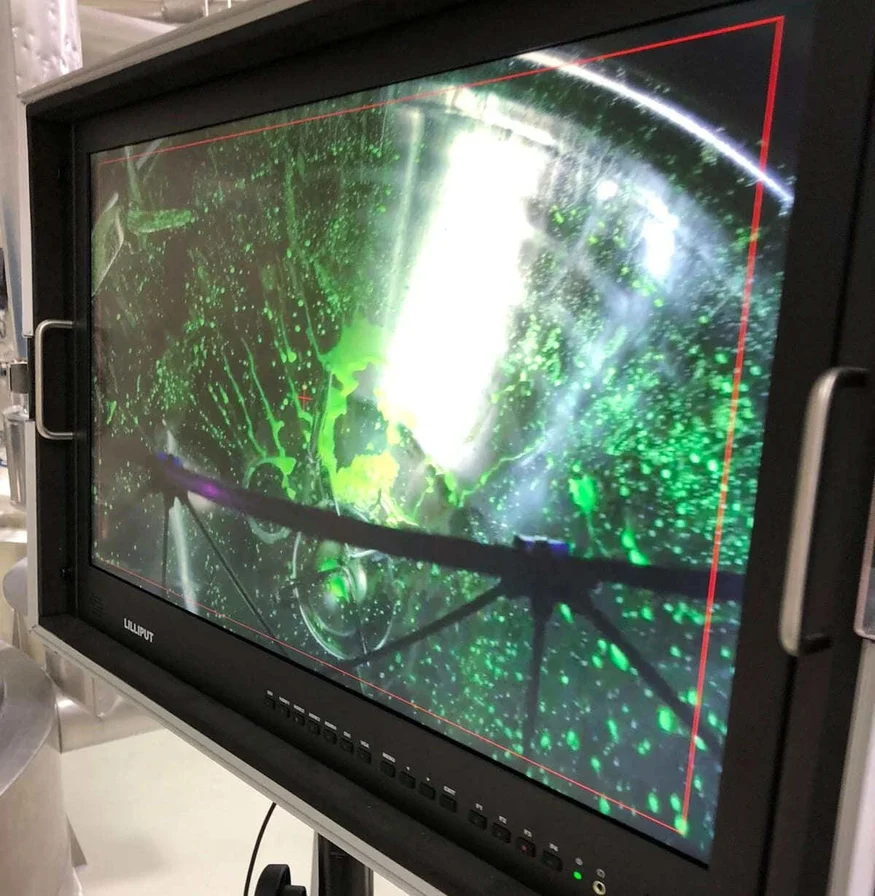

Rockenschaub successfully collected all necessary visual data using the Elios 2, completing inspections across five tanks in a single day. Through a large monitor, he live-streamed footage from the drone, effectively replacing manual entries with drone-based assessments:

1. Post-Riboflavin spraying, the Elios 2 confirmed full tank coverage.

2. Following cleaning, the drone verified the absence of any remaining Riboflavin.

*Elios 2 live-streaming data from inside a tank.*

The pharmaceutical company achieved significant advantages from AEROVISION’s drone trials:

- **Cost Efficiency**: Saved 60,000 Euros by reducing tank downtime.

- **Time Savings**: Reduced total inspection time from ten hours to four.

- **Safety Enhancements**: Prevented personnel from needing to enter hazardous environments.

- **Resource Optimization**: Lowered workforce requirements from five to three individuals.

In certain cases, the drone detected residual Riboflavin, necessitating additional cleaning cycles. While this is standard practice, traditional methods involving human entry could extend downtime.

*Elios 2 footage revealing trace Riboflavin residue.*

---

## Conclusion

Encouraged by AEROVISION’s successful Elios 2 trial, the pharmaceutical company plans to integrate drones into their routine tank inspections. As more tanks are installed over the next six months, the company intends to utilize the Elios 2 for future Riboflavin tests. Additionally, they are curious about the possibility of attaching UV lights to the drone for improved Riboflavin visualization.

This initiative underscores the growing importance of technology in enhancing safety, efficiency, and cost-effectiveness within the pharmaceutical industry.