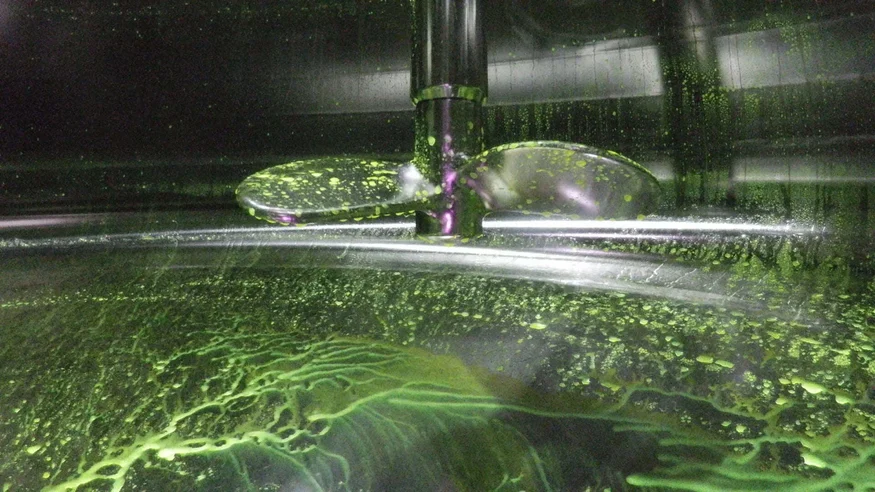

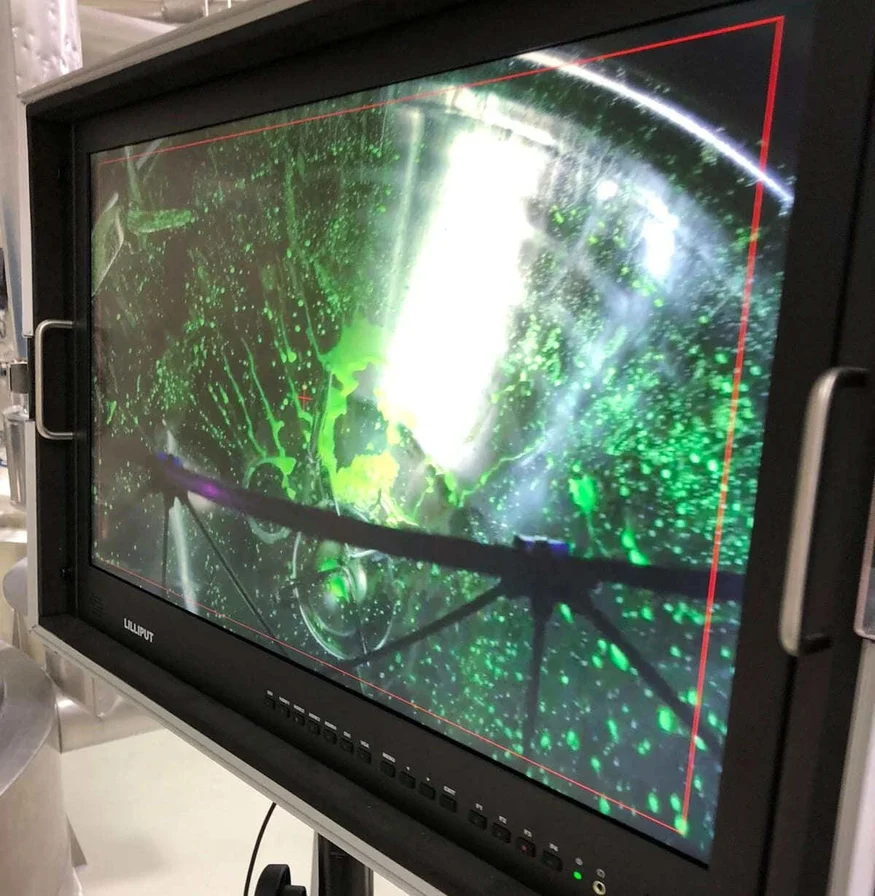

A significant pharmaceutical company recently utilized the Elios 2 drone to conduct critical tank inspections tied to Riboflavin testing. Here's what they discovered about this innovative approach. Cost Savings The Elios 2 saved the company 60,000 Euros in just one inspection cycle involving five tanks, primarily due to reduced downtime. Personnel Reduction With the Elios 2, inspectors were able to decrease the workforce from five to three individuals per inspection. Enhanced Safety The drone eliminated the need for inspectors to physically enter the tanks, significantly improving safety during inspections. Large-scale tanks are essential in pharmaceutical manufacturing, typically constructed from stainless steel for its superior cleaning properties. These tanks must remain spotless throughout production cycles. Following each production run, tanks undergo rigorous cleaning with acids and alkalis. However, whenever a new tank arrives or a revised cleaning protocol is introduced, health and safety teams must confirm that the tank is free of all contaminants and that future cleanings will be effective. This verification process involves spraying Riboflavin, a fluorescent substance, onto the tank walls using a long rod. The Riboflavin adheres to the surfaces, allowing inspectors to assess the efficacy of the cleaning procedures. Once applied, the Riboflavin is removed to verify the success of the cleaning protocols. This method is known as a Spray Shadow test or Riboflavin test. Riboflavin inside a tank Riboflavin serves as a substitute for potential contaminants, making it easier for personnel to determine whether their cleaning methods are truly effective. If any Riboflavin remains after cleaning, adjustments must be made, and the process repeated until no traces remain. Typically, two entries into the tank are necessary: one after applying the Riboflavin to confirm full coverage, and another after cleaning to ensure all traces are gone. During these entries, workers use UV lights to illuminate the Riboflavin, verifying both coverage and cleanliness. A major pharmaceutical manufacturer operates several large tanks at a facility in Austria. A production tank at the manufacturing site The company sought ways to accelerate their Riboflavin tests to minimize downtime and enhance cost-efficiency. Additionally, they aimed to conduct these inspections remotely, eliminating the need for personnel to physically enter the tanks. Markus Rockenschaub of AEROVISION Drone Support GmbH, a drone inspection service provider based in Austria, suggested testing Flyability’s Elios 2 for the upcoming Riboflavin inspections. Designed for confined space operations, the Elios 2 was deemed ideal for navigating these tanks and capturing high-quality visual data. Rockenschaub successfully collected all necessary visual data for the Riboflavin tests using the Elios 2, completing inspections on five tanks in a single day. With the help of a large monitor, he live-streamed footage from the drone, replacing manual entries with remote drone operations. First, he flew the Elios 2 into the tank after Riboflavin application to ensure full coverage. Later, after cleaning, he repeated the process to confirm no Riboflavin remained. Live-streamed data from the Elios 2 inside a tank As a result of AEROVISION’s trials, the pharmaceutical company experienced the following advantages: Economic Gains: Reduced downtime saved the company 60,000 Euros. Time Efficiency: The total time spent on five Riboflavin tests dropped from ten hours to four. Safety Improvements: Personnel no longer needed to enter the tanks. Workforce Optimization: The number of inspectors required decreased from five to three. Notably, the drone detected residual Riboflavin in some cases, requiring additional rounds of cleaning. While this is standard, traditional methods might have caused prolonged downtime because personnel would need to physically re-enter the tanks. Elios 2 footage revealing trace Riboflavin residue Encouraged by AEROVISION’s trial outcomes, the pharmaceutical firm plans to integrate the Elios 2 into more of their tank inspections. Additional tanks are set to arrive at the facility over the next six months, necessitating further Riboflavin tests where the drone could prove invaluable. Furthermore, the company is curious about the possibility of equipping the Elios 2 with UV lights, enhancing visibility during Riboflavin inspections. This innovation could offer even greater precision and efficiency in their testing procedures. Metal Storage Containers For Food Nowadays, people's lives can basically meet the requirements of food and clothing, and they are still improving. With the improvement of living standards, people have begun to have a higher pursuit for the quality of life. When purchasing various health care products, it is only reassuring to choose the ones with higher packaging levels. Even the common grains and cereals are more popular if they are properly packaged in iron boxes. Metal Storage Containers For Food,Tinplate Tin Can,Metal Food Containers,Metal Packaging Box Dongguan Tielangtou Hardware Products Co., Ltd , https://www.tinboxtlt.comMajor Pharmaceutical Firm Boosts Efficiency with Elios 2 for Tank Inspections

Key Benefits at a Glance

Introduction

Customer Requirements

AEROVISION Drone Support GmbH Offers Cutting-Edge Solution

Outcomes

Conclusion

In the past few years, many Chinese people like to pursue foreign imported products, and feel that the quality of domestic enterprises' goods is not at ease. In fact, another reason is that the domestic packaging level is not high in the early days. The gunny bag and cloth bag packaging are more sophisticated than imported products, and it is difficult to enter the high-end consumer market in terms of sales. The use of Iron Box packaging can largely ensure the quality of damaged boxes during transportation. Iron box packaging materials, patterns and colors can be better matched, and the packaging is far more exquisite than other types of packaging, thus increasing the competitiveness of products.

How to design iron box packaging for cereals?

For example, for iron box packaging of cereals and cereals, more traditional ethnic cultures, including Chinese calligraphy, paintings, poems, etc., can be added in the packaging design process, which makes ordinary help more tasteful. The combination of cereals and ethnic elements, which have been essential for people's health since ancient times, is the most suitable. However, if you want to pursue creativity, you need to add something interesting and use some novel patterns to attract consumers' attention.

Major Pharmaceutical Company Saves Using the Elios 2 for Tank Inspections