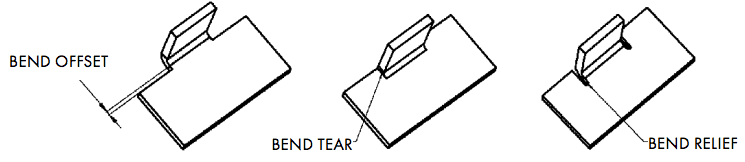

Sheet metal stamping is actually a subset of metal fabrication, but the umbrella of metal fabrication includes numerous other methods. If you're trying to decide which process best suits your metal product needs, understanding the distinctions between these approaches is crucial. Sheet metal stamping is a fabrication technique that uses dies, punches, and other specialized tools to bend, cut, punch, or shape sheet metal into the final component. This method is particularly cost-effective for large-scale production runs and can be performed in either single-stage or multi-phase operations. Progressive die stamping, for example, involves feeding a continuous strip of metal through a series of tooling stations, where each station performs specific cuts, punches, or bends. By the time the part exits the process, each station has contributed to its formation, resulting in a finished product. The advantages of sheet metal stamping include: For projects requiring large quantities of parts, sheet metal stamping could be more advantageous than general metal fabrication. However, for unique, one-off products, metal fabrication might be preferable. Keep in mind that stamping costs can increase due to tooling expenses and longer setup times. Metal fabrication refers to a broader category of manufacturing processes that include cutting, bending, and punching metals. These processes are typically more labor-intensive and take longer to complete. Metal fabrication involves reshaping raw metal materials into parts through material removal or modification. Some fabrication techniques create cutouts or holes in the metal, while others alter the shape by stretching or bending it. The benefits of metal fabrication include: While sheet metal fabrication is suitable for many metal manufacturing tasks, this method usually demands more labor and takes longer to produce parts compared to sheet metal stamping. Additionally, the cost of materials tends to be higher in metal fabrication, and certain complex designs may not be feasible. Another downside is the lack of repeatability, making it less suited for high-volume production runs. Nevertheless, this approach offers an economical and efficient way to manufacture smaller batches of simpler parts. If you need dependable sheet metal stamping services, the experts at ESI can help fulfill your requirements. Over the past three decades, we've provided top-notch manufacturing solutions and engineering support using advanced automated systems. At the start of any metal stamping project, we carefully analyze the intended use of each part, ensuring optimal performance throughout production. Our automation capabilities enhance quality control while reducing manual labor. We're equipped to handle anything from thousands to millions of parts. Our skilled workforce includes Six Sigma Black Belt-trained QA personnel, ensuring superior quality across all our offerings. For more details about our capabilities and to initiate your next project with us, request a quote today. Medium-sized Courtyard Scrubber The medium-sized courtyard scrubber is suitable for cleaning the floor of a large garden, with simple operation and high efficiency. Medium-Sized Courtyard Scrubber,Floor Pressure Washer,Household Portable High Pressure Washer,Portable Car Pressure Washer Ningbo Senmiao Trading Co., Ltd. , https://www.nbsenmiao.com When it comes to producing metal parts and components, some industries might opt for sheet metal stamping or other forms of metal fabrication. Many people often confuse the terms "sheet metal stamping" and "metal fabrication," but they represent distinct manufacturing processes with key differences.

When it comes to producing metal parts and components, some industries might opt for sheet metal stamping or other forms of metal fabrication. Many people often confuse the terms "sheet metal stamping" and "metal fabrication," but they represent distinct manufacturing processes with key differences.

What Is Metal Fabrication?

Quality Metal Stamping Services from Engineering Specialties, Inc.

There are some minor issues that need to be paid attention to in the process high-pressure cleaners, which are summarized as follows:

1. When operating the high pressure washer: Always wear proper goggles, gloves and masks.

2. When the Spray Gun of the high pressure washer is not used, the setting trigger must always be locked in a safe state.

3. Always check all the electrical connections of the high pressure washer.

4. Frequently check all the high-pressure cleaner fluids.

5. Always keep hands and feet away from the cleaning nozzle.

6. Before disconnecting the hose, always release the pressure in the Washing Machine.

7. Always use low pressure to work as much as possible, but the pressure must be sufficient to complete the work.

8. Never start the equipment before turning on the water supply and allowing proper water to flow through the spray gun stem. Then connect the required cleaning nozzle to the spray gun stem

superior.

9. Always drain the water in the hose after each use.

Sheet Metal Stamping vs. Metal Fabrication

Comments are closed