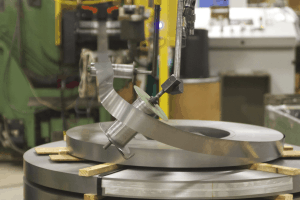

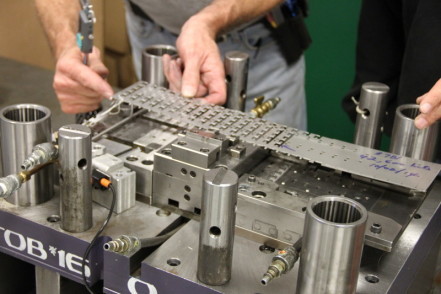

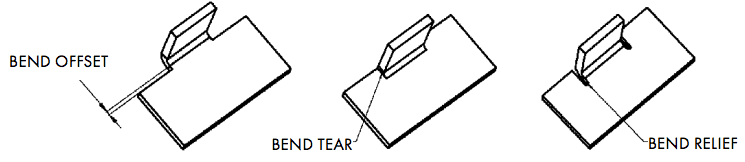

Sheet metal stamping is a highly efficient way to produce large quantities of identical parts, especially when precision and consistency are key. This method uses dies and punches to shape the metal into the desired form, making it ideal for industries like automotive and electronics where high-volume production is common. On the other hand, metal fabrication is a more versatile approach that includes everything from cutting and bending to welding and assembly. It's typically used for custom projects or small-batch orders where flexibility is essential. Sheet metal stamping is a specialized fabrication technique that relies on precision dies and punches to form metal sheets into intricate shapes. Whether you're dealing with simple cuts or complex multi-stage operations, this method offers unmatched efficiency and accuracy. Progressive die stamping, for example, allows a continuous strip of metal to pass through multiple stations, each adding layers of complexity until the final product emerges. The benefits of sheet metal stamping include: However, sheet metal stamping isn't always the best choice. Tooling costs can be high, and the setup time might be lengthy for smaller batches. If you need a more flexible solution for prototypes or one-offs, metal fabrication could be the better option. Metal fabrication covers a wide array of methods used to shape and assemble metal parts. From basic cutting and bending to advanced welding and machining, this field offers immense versatility. One common technique is laser cutting, which provides unparalleled precision and speed, while another is plasma cutting, which excels at handling thicker metals. Both methods allow for quick design changes and adaptability to various materials. The advantages of metal fabrication include: Despite its flexibility, metal fabrication tends to be more labor-intensive and time-consuming than sheet metal stamping. Additionally, material costs are usually higher, and achieving uniformity across large quantities can be challenging. Looking for reliable sheet metal stamping solutions? Look no further than Engineering Specialties, Inc. (ESI). With over 30 years of experience, we pride ourselves on delivering top-tier manufacturing services using cutting-edge technology. Whether you're producing thousands or millions of parts, our automated systems ensure consistent quality and efficiency. Our team consists of highly trained professionals, including Six Sigma Black Belt-certified Quality Assurance personnel, ensuring excellence in every step of the process. Need help with your next project? Contact us today to request a quote and discover how we can support your manufacturing goals.

1. Environmental protection and regeneration. At present, the problem of environmental protection is getting more and more serious, and countries around the world have a deep understanding of environmental protection. The concept of "plasticizing with paper tape" has been around for a long time, and paper as an environmentally friendly and recycled product is its value. And it will continue to develop in the near future.

2. Low cost. The overall cost of using paper for packaging is relatively low, which is in line with the merchants` demand for cost control and also in line with the long-term development trend of the market.

3. Simple style. The packaging style of white kraft paper is simple and atmospheric, and its retro characteristics are also favored by consumers. The reason why many well-known brands use kraft paper for packaging is because of its simple and retro characteristics.

4. Physical characteristics. Non-toxic, odorless, non-polluting, high strength, good air permeability, abrasion resistance, etc.

White Paper Bowl,White Paper Soup Bowl,Hot Soup Paper Bowl Disposable,Disposable Food Bowl Ningbo Senmiao Trading Co., Ltd. , https://www.nbsenmiao.com When it comes to manufacturing metal parts and components, people often confuse the terms "sheet metal stamping" and "metal fabrication," even though they refer to very distinct processes. While sheet metal stamping is a specific type of fabrication, metal fabrication encompasses a much broader set of techniques used in metalworking.

When it comes to manufacturing metal parts and components, people often confuse the terms "sheet metal stamping" and "metal fabrication," even though they refer to very distinct processes. While sheet metal stamping is a specific type of fabrication, metal fabrication encompasses a much broader set of techniques used in metalworking.Understanding Sheet Metal Stamping

Exploring Metal Fabrication Techniques

Quality Metal Stamping Services from Engineering Specialties, Inc.

Sheet Metal Stamping vs. Metal Fabrication

Comments are closed