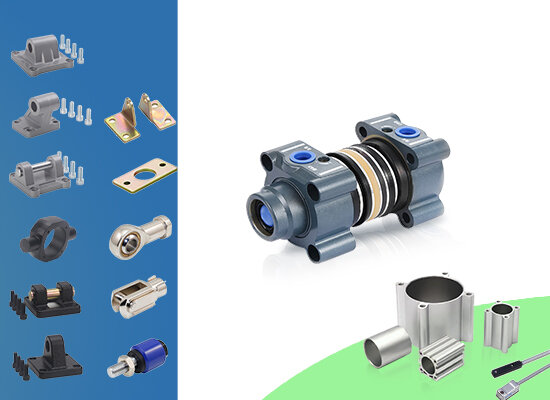

Pneumatic Cylinder Accessories Air cylinder accessories of different models and different standards are generally not interchanged. When ordering Pneumatic Cylinder accessories, please note the specifications and parameters of the corresponding cylinder. If the standard and model of the cylinder are same, the cylinder accessories can be used interchangeably.Pneumatic Cylinder Tube. Pneumatic cylinder is the executing component in pneumatic systems, mainly used to convert the pressure energy of compressed air into mechanical energy, generating linear or oscillatory motion. The construction of pneumatic cylinders is complex and includes multiple key components. Below are some common components and their functions: Cylinder Barrel: This is the main body of a cylinder, typically a cylindrical container used to accommodate pistons and other internal components. The cylinder barrel must be strong enough to withstand the pressure of compressed air inside. Piston: located inside the cylinder and in close contact with the inner wall of the cylinder barrel. When compressed air enters the cylinder, the piston moves inside the cylinder barrel, generating thrust or tension. Piston Rod: The part that connects the piston to the external mechanical structure and is used to transmit the linear motion of the piston. End caps/caps: fixed at both ends of the cylinder barrel, sealing the internal space of the cylinder and supporting the piston rod and other components. The front cover usually includes a guiding component for the piston rod. Seals: Used to prevent gas leakage and ensure smooth movement of the piston within the cylinder barrel. It mainly includes piston sealing rings, rod sealing rings, and dust sealing rings. Guide bushing: Helps the piston rod maintain the correct direction of movement, reducing friction and wear. Buffer Device: Some cylinders are equipped with buffer devices to slow down the speed of piston movement when it reaches the end point, preventing impact and noise. Magnetic switches: Some cylinders have built-in or external magnetic switches used to detect the position of the piston and control the action of the cylinder. Exhaust Flow Control Valve: Sometimes integrated into the cylinder, it is used to regulate the exhaust speed and control the speed of the piston. These components work together to enable the pneumatic cylinder to effectively convert the energy of compressed air into the required mechanical motion. According to specific application requirements, pneumatic cylinders may also include other specially designed components to meet specific functional requirements. Pneumatic Cylinder Accessories,Pneumatic Cylinder Parts Foshan Weiyingjia Technology Co., Ltd , https://www.wyspneumatic.com

The 250,000th engine off-line firewood mode creates new heights

At 11 a.m. on November 14, in the modern factory of Weichai Holding Group, a significant milestone was reached as the 250,000th engine product of the year was successfully launched. This achievement marked a major success for the group's engine business, which has been steadily growing and maintaining its leadership in the industry. During the ceremony, Tan Xuguang, Chairman of Weichai Holding Group, personally handed over this special engine to dealer Le Zhongyang, symbolizing not only a record but also a new chapter in the company's history.

This milestone came just before mid-November, with the number of high-power engines produced and sold in 2007 reaching 250,000 units. It is not only a historic achievement for Weichai itself but also a remarkable breakthrough in global high-speed, high-power engine manufacturing. The company continues to write its own story of rapid and sustainable development, reinforcing its position as a leader in the power industry.

Weichai engines have long been favored by customers for their reliability and advanced technology. Over the years, users have come to trust and appreciate the performance of Weichai products, contributing to the brand’s reputation as "China's Leading Power Brand." As a result, Weichai engines are often the preferred choice for many users across both domestic and international markets.

Le Zhongyang, who received the 250,000th engine, shared his experience of using Weichai marine engines for many years. He noted that these engines offer better fuel efficiency, reliability, and ease of maintenance, leading to higher income compared to other products. With his growing economic strength, he has become a local distributor of Weichai, strengthening their partnership. He expressed confidence in the future of their collaboration, citing Weichai's strong brand and technological capabilities as key drivers for continued growth.

The ship engine market has always been a core area for Weichai, where it holds over 80% market share. In recent years, the company has expanded into new sectors such as heavy trucks and construction machinery, achieving a dominant market position. The WD615 engine set a monthly sales record of 30,000 units, while the newly launched WD12 engine, within less than a year, achieved over 10,000 units in production and sales. Industry observers expect annual sales to reach 1.5 million units, with the WD12 becoming a highly sought-after model.

According to statistics, as of June this year, Weichai’s market share in heavy-duty vehicles (over 14 tons) reached 36%, up 9 percentage points from the previous year. In the loader market (over 5 tons), the share increased by 3 percentage points to 81%, further solidifying Weichai's competitive edge.

Innovation has been at the heart of Weichai’s growth. From initial technology absorption to independent research and development, the company has consistently delivered cutting-edge products. Notable achievements include the first China-owned Blue Engine meeting Euro III standards, the mature WD12 large-displacement engine, and the successful development of the Euro IV engine. These innovations have positioned Weichai as a leader in China's engine industry, driving it toward global recognition.

Tan Xuguang emphasized that the 250,000th engine is more than a milestone—it reflects the company's vitality and growth. Looking ahead, Weichai will continue to focus on innovation, leveraging advanced technology platforms to develop more environmentally friendly and energy-efficient engines. The goal is to establish the largest and most technologically advanced engine production base in the industry.

Weichai's technological progress mirrors the evolution of China's diesel engine industry. Since 1999, the company has led the upgrade of construction machinery engines, significantly enhancing competitiveness. With the rise of heavy trucks and highway construction, Weichai introduced engines with increasing horsepower, keeping pace with market demand. The company also played a crucial role in meeting emission standards, developing the first Euro III engine in 2005 and the Euro IV engine in 2007. Additionally, Weichai has been involved in new energy engine R&D projects, collaborating with international partners to develop CNG, LPG, and LNG engines that meet Euro IV standards and are exported globally.

Through relentless efforts in innovation and technological advancement, Weichai has maintained its leadership in product and technology. It continues to narrow the gap with global leaders while expanding its influence internationally. The company has achieved consistent growth, creating what is known as the "Weichai Speed" — doubling in size for five consecutive years, ensuring healthy and rapid development.

As the largest manufacturer of high-power and high-speed diesel engines in China, Weichai has built a strong brand and global presence. Its two listed companies, Weichai Power and Shandong Juli, along with its diverse product range, reflect its comprehensive strength. Through innovative capital operations, Weichai has driven enterprise development forward, forming a complete heavy-duty vehicle industry chain that includes engines, gearboxes, axles, and complete vehicles.

With a wide power range and high brand loyalty, Weichai continues to lead in the marine and power generation sectors. By integrating resources and focusing on joint market strategies, the company has enhanced its competitiveness, created opportunities for market maximization, and improved profitability. Weichai remains a powerhouse in the global engine industry, continuously evolving and expanding its influence.

Pneumatic air cylinder accessories mainly include cylinder mounting brackets, piston rod connecting joints, repair sealing parts, magnetic reed switch, as well as cylinder assembly kits and cylinder barrels, piston rods etc.Air Cylinder Tube.