The Han Dao sword, also known as the Han Sword, is a traditional Chinese weapon that originated during the Han Dynasty (206 BC – 220 AD). It is a single-edged, curved sword that is typically used in Chinese martial arts, particularly in the styles of Tai Chi and Kung Fu. Han Dao Sword, Chinese Han Dao, Han Dynasty Sword Ningbo Autrends International Trade Company , https://www.longquan-swords.com

The length of the Han Dao sword can vary, but it is usually around 70-80 centimeters long, with a handle that is about one-third of the overall length. The handle is traditionally made of wood, with a guard and pommel made of metal.

The Han Dao sword is primarily used as a slashing weapon, with its curved blade allowing for quick and powerful strikes. It is often used in combination with circular and flowing movements, making it a graceful and elegant weapon to watch in action.

In addition to its use in martial arts, the Han Dao sword also has a long history as a military weapon. During the Han Dynasty, it was commonly used by infantry soldiers, and it continued to be used by various armies throughout Chinese history.

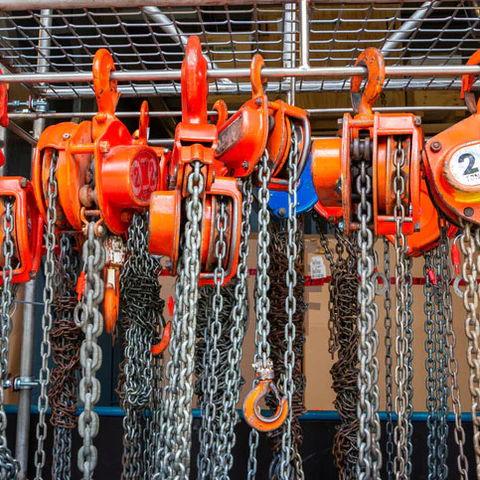

Lifting with Confidence: Quality Chain Blocks for Safety

Chain blocks, also known as chain hoists, are indispensable tools across many industries, providing a dependable and effective method for lifting and relocating heavy loads. Whether you're in construction, manufacturing, or simply a DIY hobbyist, grasping the fundamentals of chain blocks is vital for executing safe and successful lifting tasks.

Take a look at this image showcasing a compact chain block:

### Understanding the Basics of Chain Blocks

#### What is a Chain Block?

A chain block, or chain hoist, is a mechanical device used to lift heavy loads by applying force via a chain. It includes a chain, a series of pulleys, and several components that facilitate smooth and controlled lifting.

#### Key Components of a Chain Block

Chain blocks generally consist of critical parts like hooks, load chains, gears, and braking systems. Hooks offer a secure connection point for lifting items, while load chains, made of high-strength steel, bear the weight of the load. Gears and braking mechanisms ensure controlled lifting and stop the load from slipping.

Each part of a chain block is essential for ensuring the safety and effectiveness of the lifting process. Gears transmit force, amplifying the input force to lift heavy loads effortlessly. Braking mechanisms automatically engage if there’s a sudden drop in the load, preventing accidents and safeguarding operators.

### Different Types of Chain Blocks

#### Manual Chain Blocks

Manual chain blocks are the most common type and are operated manually. They are reliable, cost-effective, and perfect for light to medium-duty lifting tasks. Suitable for construction, workshops, and maintenance work, manual chain blocks are valued for their simplicity and portability.

One significant advantage of manual chain blocks is their straightforwardness and user-friendliness. Since they rely solely on human effort, they are highly mobile and versatile. Manual chain blocks are often chosen in places where access to electricity or hydraulic power is restricted, such as outdoor construction sites or remote areas.

Here’s an example of a manual chain block in action:

#### Electric Chain Blocks

Electric chain blocks, powered by electricity, provide a more efficient lifting solution for heavier loads. Equipped with electric motors, they deliver the necessary power for lifting operations. Commonly used in factories, warehouses, and construction sites where frequent lifting is needed, electric chain blocks are prized for their consistency and precision.

One standout feature of electric chain blocks is their ability to offer smooth and controlled lifting. The electric motors ensure steady and exact lifting, minimizing the risk of sudden movements or jerks that can happen with manual chain blocks. This makes electric chain blocks especially suited for lifting delicate or valuable items that demand extra care.

### How Chain Blocks Function

#### The Mechanics of Lifting

When using a chain block, force is applied to the load chain, causing it to wind around the gears and lift the load. As the load rises, the gears turn, and the load chain moves through the pulleys. This mechanical advantage lets the operator lift heavy loads with minimal physical effort.

Chain blocks come in various sizes and weight capacities to accommodate different lifting demands. The design of the gears and pulleys in a chain block is crucial for its efficient operation. The gears are usually made of durable materials like steel to endure the heavy loads they lift, while the pulleys are positioned to guide the load chain smoothly during lifting.

#### Safety Mechanisms in Chain Blocks

Chain blocks are built with multiple safety features to protect both the operator and the load. These safety mechanisms include overload protection, which stops the chain block from lifting loads exceeding its capacity, and load brakes that automatically engage when the lifting operation halts or when the load remains stationary.

Moreover, chain blocks frequently have a safety latch on the hook to keep the load secure during lifting and avoid accidental slippage. Regular maintenance and inspections are essential to ensure these safety features are working properly and that the chain block remains in excellent working order for safe lifting operations.

Here’s another image highlighting chain blocks in action:

### Choosing the Right Chain Block

#### Determining Your Lifting Needs

Before picking a chain block, it’s important to evaluate your lifting requirements, including the weight of the load and the height to be lifted. It's crucial to select a chain block with the appropriate lifting capacity and height to ensure safe and efficient operations.

When considering the weight of the load, it’s essential to account for any possible future increases in load size or weight. Opting for a chain block with a slightly higher lifting capacity than your current needs can provide flexibility for future demands, eliminating the need for frequent replacements or upgrades.

#### Evaluating Chain Block Quality and Safety Features

When buying a chain block, quality and safety should be top priorities. Look for chain blocks that adhere to international safety standards and have undergone rigorous testing. Consider features like load limiters, corrosion resistance, and ease of maintenance to ensure a reliable and long-lasting chain block.

Additionally, it’s wise to check for certifications or accreditations from reputable organizations that confirm the quality and safety standards of the chain block. These certifications can provide assurance that the product has been manufactured to meet specific criteria and has passed stringent quality checks.

By comprehending the basics, types, and operational principles of chain blocks, you can make informed choices when it comes to selecting and using these invaluable lifting tools. Always prioritize safety, and remember that regular maintenance and inspections are key to maintaining the performance and longevity of your chain block.