The Tanto was primarily used as a weapon by samurais and was often carried as a secondary weapon alongside a longer sword, such as a katana. It was designed for close-quarters combat and was used for stabbing and slashing. Tanto Folding Knife, tanto blade, tanto sword,Tanto Katana Ningbo Autrends International Trade Company , https://www.longquan-swords.com

The blade of the Tanto is usually made from high-quality steel and is known for its sharpness and durability. The handle is traditionally made from wood and is wrapped with a cord for a secure grip. Some Tanto may also feature decorative elements such as ornate carvings or inlays.

In addition to its use as a weapon, the Tanto also had ceremonial and symbolic significance in Japanese culture. It was often given as a gift or used in rituals and ceremonies.

Today, the Japanest Tanto continues to be appreciated for its craftsmanship and historical significance. It is often collected as a piece of art or used in martial arts training.

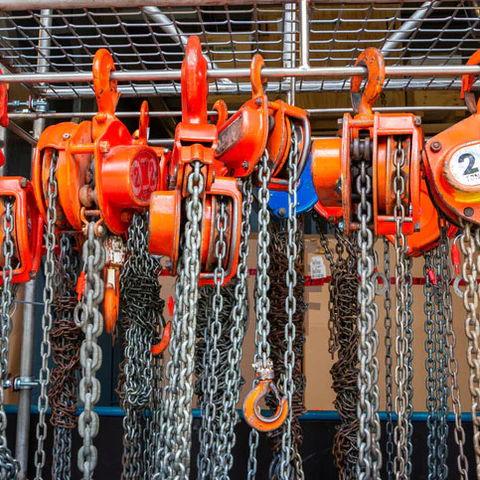

Lifting with Confidence: Quality Chain Blocks for Safety

Chain blocks, also referred to as chain hoists, are indispensable tools across many industries, providing a dependable and effective way to lift and move heavy loads. Whether you're involved in construction, manufacturing, or simply a DIY enthusiast, having a grasp of the fundamentals of chain blocks is vital for carrying out safe and successful lifting tasks.

## Understanding the Basics of Chain Blocks

### What Is a Chain Block?

A chain block, or chain hoist, is a mechanical device used to lift heavy loads by applying force through a chain. It comprises a chain, a set of pulleys, and several components that facilitate smooth and controlled lifting.

### Key Components of a Chain Block

Chain blocks generally feature essential components like hooks, load chains, gears, and braking systems. Hooks provide a secure attachment point for lifting objects, while load chains, made of high-strength steel, bear the load weight. Gears and braking mechanisms ensure controlled lifting and stop the load from slipping.

Each component of a chain block plays a critical role in guaranteeing the safety and efficiency of the lifting process. Gears allow for the transfer of force, multiplying the input force to lift heavy loads effortlessly. Braking mechanisms are designed to engage automatically if there’s a sudden drop in the load, preventing accidents and ensuring operator safety.

---

## Different Types of Chain Blocks

### Manual Chain Blocks

Manual chain blocks are the most common type and are operated manually. They are reliable, budget-friendly, and ideal for light to medium-duty lifting tasks. Suitable for construction sites, workshops, and maintenance work, manual chain blocks are favored in situations where access to electricity or hydraulic power is limited, such as outdoor construction areas or remote locations.

One significant advantage of manual chain blocks is their simplicity and ease of use. They only require human effort, making them highly portable and adaptable. Their lack of reliance on external power sources makes them especially practical in places where electricity isn’t readily available.

### Electric Chain Blocks

Electric chain blocks, powered by electricity, offer a more efficient solution for lifting heavier loads. Equipped with electric motors, they provide the necessary power for lifting operations. Commonly found in factories, warehouses, and construction sites where frequent lifting is required, electric chain blocks are highly valued for their efficiency.

A key feature of electric chain blocks is their ability to provide consistent and controlled lifting operations. Electric motors ensure smooth and precise lifting, minimizing the risk of sudden movements or jerks that can happen with manual chain blocks. This makes electric chain blocks particularly suitable for delicate or valuable loads that demand extra care.

---

## How Chain Blocks Work

### The Mechanics of Lifting

When a chain block is in action, force is applied to the load chain, causing it to wrap around the gears and lift the load. As the load rises, the gears rotate, and the load chain moves through the pulleys. This mechanical advantage allows the operator to lift heavy loads with minimal physical effort.

Chain blocks come in various sizes and weight capacities to suit different lifting needs. The design of the gears and pulleys in a chain block is crucial for its efficient operation. Gears are usually made of durable materials like steel to withstand heavy loads, while pulleys are positioned strategically to guide the load chain smoothly during lifting.

### Safety Mechanisms in Chain Blocks

Chain blocks are designed with several safety features to protect both the operator and the load. These include overload protection, which stops the chain block from lifting loads beyond its capacity, and load brakes that automatically engage when the lifting operation halts or when the load is stationary.

Additionally, chain blocks often have a safety latch on the hook to secure the load during lifting and prevent accidental slipping. Regular maintenance and inspections are essential to ensure that these safety features are functioning correctly and that the chain block remains in optimal working condition for safe lifting operations.

---

## Choosing the Right Chain Block

### Determining Your Lifting Needs

Before selecting a chain block, it's crucial to evaluate your lifting requirements, including the weight of the load and the height it needs to be lifted. It's essential to pick a chain block with the appropriate lifting capacity and height to ensure safe and efficient operations.

When considering the weight of the load, it's important to account for potential future increases in load size or weight. Opting for a chain block with a slightly higher lifting capacity than your current needs can provide flexibility for future requirements, avoiding the need for frequent replacements or upgrades.

### Evaluating Chain Block Quality and Safety Features

When buying a chain block, quality and safety should be primary concerns. Look for chain blocks that adhere to international safety standards and have undergone rigorous testing. Consider features like load limiters, corrosion resistance, and ease of maintenance to ensure a reliable and long-lasting chain block.

It's also wise to check for certifications or accreditations from reputable organizations that validate the quality and safety standards of the chain block. These certifications can assure that the product meets specific criteria and has passed stringent quality checks.

By grasping the basics, types, and working principles of chain blocks, you can make informed decisions when it comes to selecting and operating these valuable lifting tools. Always prioritize safety, and remember that regular maintenance and inspections are crucial to ensure continued performance and longevity of your chain block.